Gas Safety Engineering

Safety devices, gas non-return valves and gas hose couplings

All safety devices and gas hose couplings are design type-tested and are subject to constant production monitoring by neutral test institutes, such as BAM and UL. The safety devices in accordance with EN ISO 5175-2 (check valves and flashback-resistant gas non-return valves) are tested by BAM and approved by DVGW.

- More...

As worldwide leading manufacturer we supply gas safety devices and gas hose couplings with worldwide standardized thread and hose connections. We offer the IBEDA testing unit, type PV-GD, for testing of gas safety devices for gas return and gas flow according to the country specific regulations.

- Difference in the standards EN ISO 5175-1 and EN ISO 5175-2

Safety devices in accordance with EN ISO 5175-1 come with integrated flame arrestor stopping a flashback also when using fuel gas and oxygen mixtures, for example acetylene/oxygen mixtures.

Safety devices in accordance with EN ISO 5175-2 are configured without integrated flame arrestor. They stop a flashback when using fuel gas and compressed air mixtures (not flashback-resistance when using acetylene as fuel gas).

Gas non-return valves (check-valves) in accordance with EN ISO 5175-2 prevent reverse flow of gas. They are not designed to stop flashbacks.

Products Flashback

arrestorsGas non-

return valvesCheck valves Standard EN ISO 5175-1 EN ISO 5175-2 EN ISO 5175-2 Flame arrestor yes no no Prevention of reverse

flow of gasTechnical gases yes yes yes Resistance against

flashbackFuel gas/compressed air mixture yes except Acetylene no Fuel gas/oxygen mixture yes no no - Gas Safety Devices according to EN ISO 5175-1

Gas safety devices according to EN ISO 5175-1 (flashback arrestors with integrated flame arrestor) for welding, cutting and allied processes.

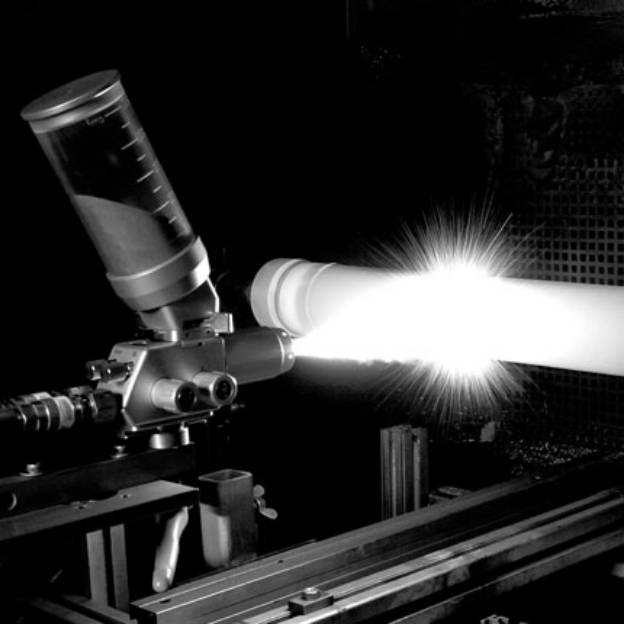

IBEDA flashback arrestors are manufactured to international standards (EN ISO 5175-1) and regulations (TRAC207 - flashback arrestors) and are independently certified by leading institutes like the German BAM and the American UL. All flashback arrestors are 100% tested according to EN ISO 5175-1. The function of the flame arrestor, the gas non-return valve and the leak-tightness is tested. During the testing process, the integrated flame barrier is subjected to a flashback with the most explosive gas mixture at its maximum pressure.

IBEDA offers a special testing device for the annual inspection of safety devices which is to be conducted in accordance with country specific regulations on flow rate, gas non-return and leak tightness. The PVGD is an easily handled testing unit designed to provide quick and uncomplicated testing.

As worldwide leading manufacturer we supply gas safety devices with worldwide standardised thread and hose connections.

- Application of safety devices according to EN ISO 5175-1

The IBEDA product range on gas safety devices (flashback arrestors with flame arrestor) according to EN ISO 5175-1 are used in different various industries. The flashback arrestors can be used on single cylinders (regulator mounted), on torches as well as on cutting machines. Furthermore, it is the ideal protection at cylinder regulators, distribution lines, tapping points and gas distributors (board connection block). The flashback arrestors (FBA) offer a gas non-return valve (check valve), a flame arrestor (flame barrier) as well as a thermal cut-off valve. The IBEDA flashback arrestor (FBA) is suitable for all standard gas types. These arrestors with multiple safety functions provide optimal protection against flashback, gas return and additionally against burnback if the safety device type includes a thermal cut-off valve.

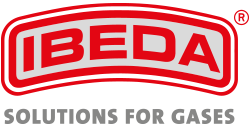

- Gas non-return valves according to EN ISO 5175-2 (without flame arrestor)

IBEDA gas non-return valves (safety devices) in accordance with EN ISO 5175-2 (without integrated flame barrier) applicable as check valves for thermal processes that are operated with mixtures of fuel gas and air, or as flashback-resistant gas non-return valves.

All safety devices according to EN ISO 5175-2 (check valves and flashback-resistant non-return valves) are tested by BAM in Berlin and are DVGW certified. The valve systems are specially developed for low cracking pressures of about 4 mbar. The gas non-return valves reliably prevent the reverse flow of gas.

Flashback-resistant valves additionally stop flashbacks if fuel gas and compressed air mixture is used. All check valves and flashback-resistant gas non-return valves are subjected to a 100% quality test. The leak-tightness and the function of the gas non-return valve are tested.

- Application of safety devices according to EN ISO 5175-2

The check valves, as well as the flashback-resistant gas non-return valves are used to protect thermal process plants to EN746-2, pipeline systems, and tapping points.

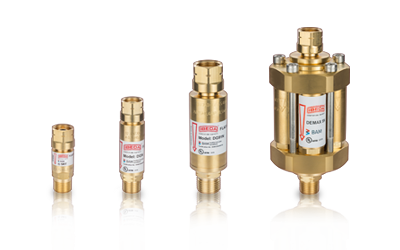

- Gas hose couplings according to EN 561 or ISO 7289

Gas hose couplings (Gas quick-action couplings) according to EN 561 or ISO 7289 for welding, cutting and allied processes. IBEDA quick connectors come in three different gas connections for fuel gas (acetylene, propane, natural gas, hydrogen), oxygen and inert gas (CO2, argon, nitrogen).

All gas hose couplings are design type-tested and are subject to constant production monitoring by neutral test institutes, such as BAM. They are submitted to a 100% quality test. The leak-tightness at maximum working pressure and the function of the integrated gas non-return valve are tested. We supply gas safety devices and gas hose couplings with worldwide standardised thread and hose connections.

- Application of quick-action couplings according to EN561 or ISO7289

The IBEDA product portfolio on gas hose couplings (quick connectors) has been proven for decades already. The quick-action couplings are quick and easy to install and a gastight connection can be created without using any tool. The quick couplers are available in different versions. Owing to conformance with the standards EN 561 and ISO 7289, IBEDA hose couplings are compatible with standard systems worldwide. Furthermore we offer quick couplings for high flow rates. Design-type tests and special voluntary tests by the Federal Institute for Materials Research and Testing (BAM) prove the outstanding quality of the IBEDA manufactured couplings.