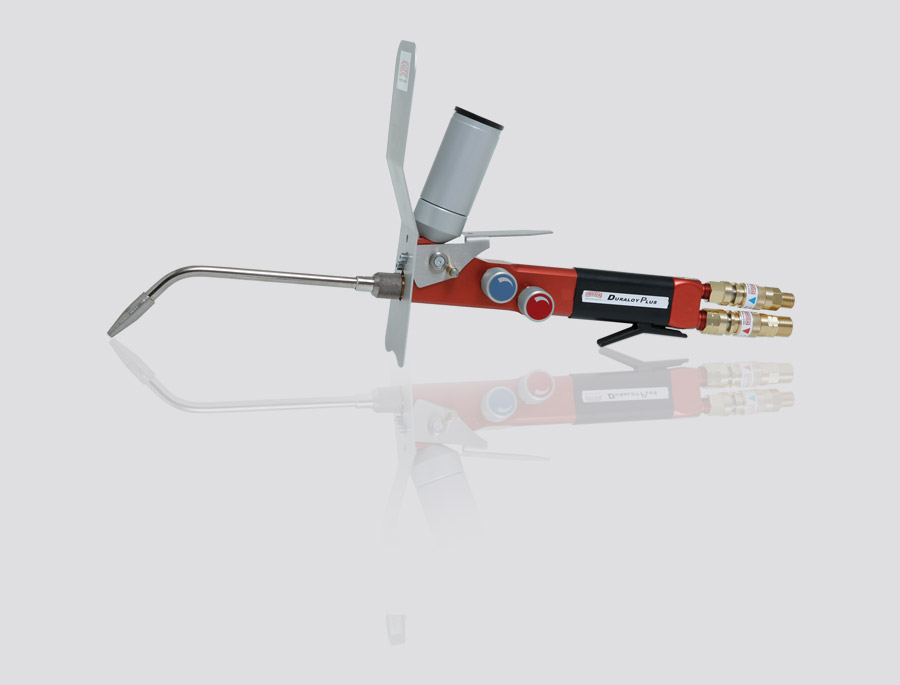

DURALOYPLUS

Powder spray torch

Highlights

- Modular design

- Easy fit welding/heating attachments

- Easy to change in the field of application

- Cost efficient by using standard components and standard spare parts

- High level of operational safety

- Easy to use on components which are difficult to access

- Tungsten Carbide inserts available for use with carbide powders (optional)

- Quick action couplings according to EN 561 for the gas hoses

- Safety devices according to EN ISO 5175-1 (optional)

- Accessories are easy to fit and to adjust

- Cost efficient operating materials (Acetylene, Oxygen)

- Quick-action shut-off valve

- Heating shield

Powder spray torch for thermal spraying with self-fluxing alloys and melting at the same time. Most types of metal can be coated with the the DURALOYPLUS torch, provided that the melting point is higher than the working temperature of the alloy. During the operation, the powder particels pass through the flame and onto the surface of the work piece. The bonding is achieved by fusion with the parent metal.

In comparison to the DURALOY, the DURALOYPLUS torch offers an even more comfortable handling by the integrated quick-action shut-off valve. When operation is interrupted, the gas mixture, which was adjusted previously, is maintained. Therefore, it is not necessary to spend any time re-adjusting the mixture when setting up the re-operation. This is advantageous for applications with frequent interruptions of work.

Data sheet

CONTENTS OF THE DURALOYPLUS Kit:

- DURALOYPLUS torch with quick-action shut-off valve, powder cartridge and adapter for UTP HA-Bond powder cartridge

- Heating shield

- Welding tips size 1-5

- Heating tips size 4 and 5

- Coupling Pin D1 and coupling DKG for Oxygen and Acetylene

- Igniter