Fuel gas properties

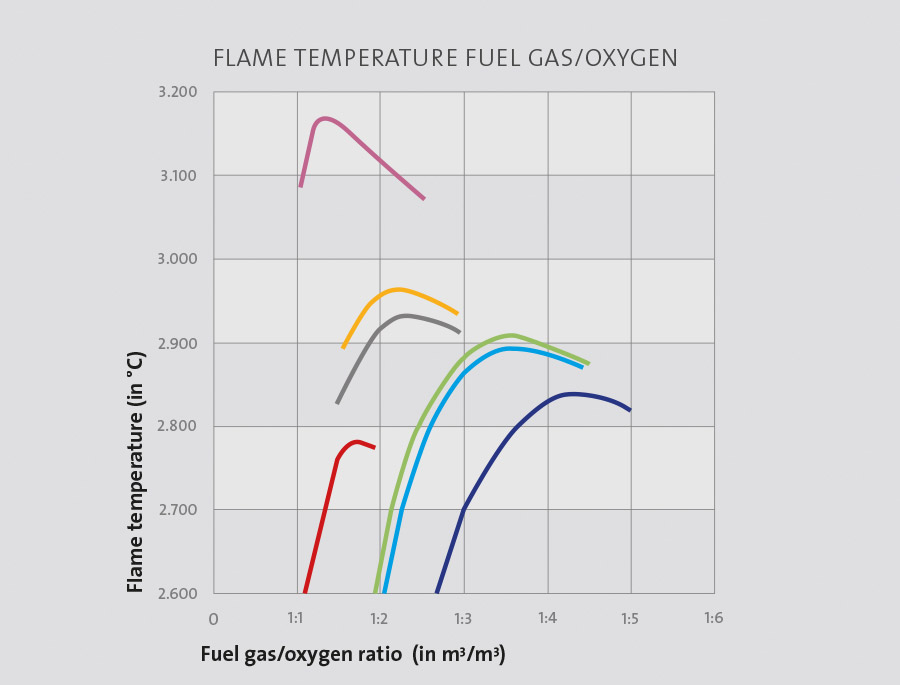

A high temperature fuel gas/oxygen flame produces a quick increase of temperature on the surface of the work piece. A fuel gas/air flame works with a lower temperature (due to the amount of nitrogen in the air).

The autogenous engineering includes various different processes, such as flame heating, flame cleaning, flame brazing, flame hardening and flame sintering. For all these processes a flammable gas is used such as acetylene, hydrogen, propane, butane, and ethane in combination with oxygen, compressed air or ambient air.

Use of the flame brazing process allows for bonding of various materials. This is achieved by using a melted additive – the solder. Brazing is mainly applied with copper and its various composite materials as well as Aluminium and materials with limited suitability for fusion welding processes.

The flame straightening is used in many applications. With a flame straightening burner defects can be eliminated and the required shapes of parts can be achieved, even for large work pieces common in ship building, tank construction or steel industry for example.