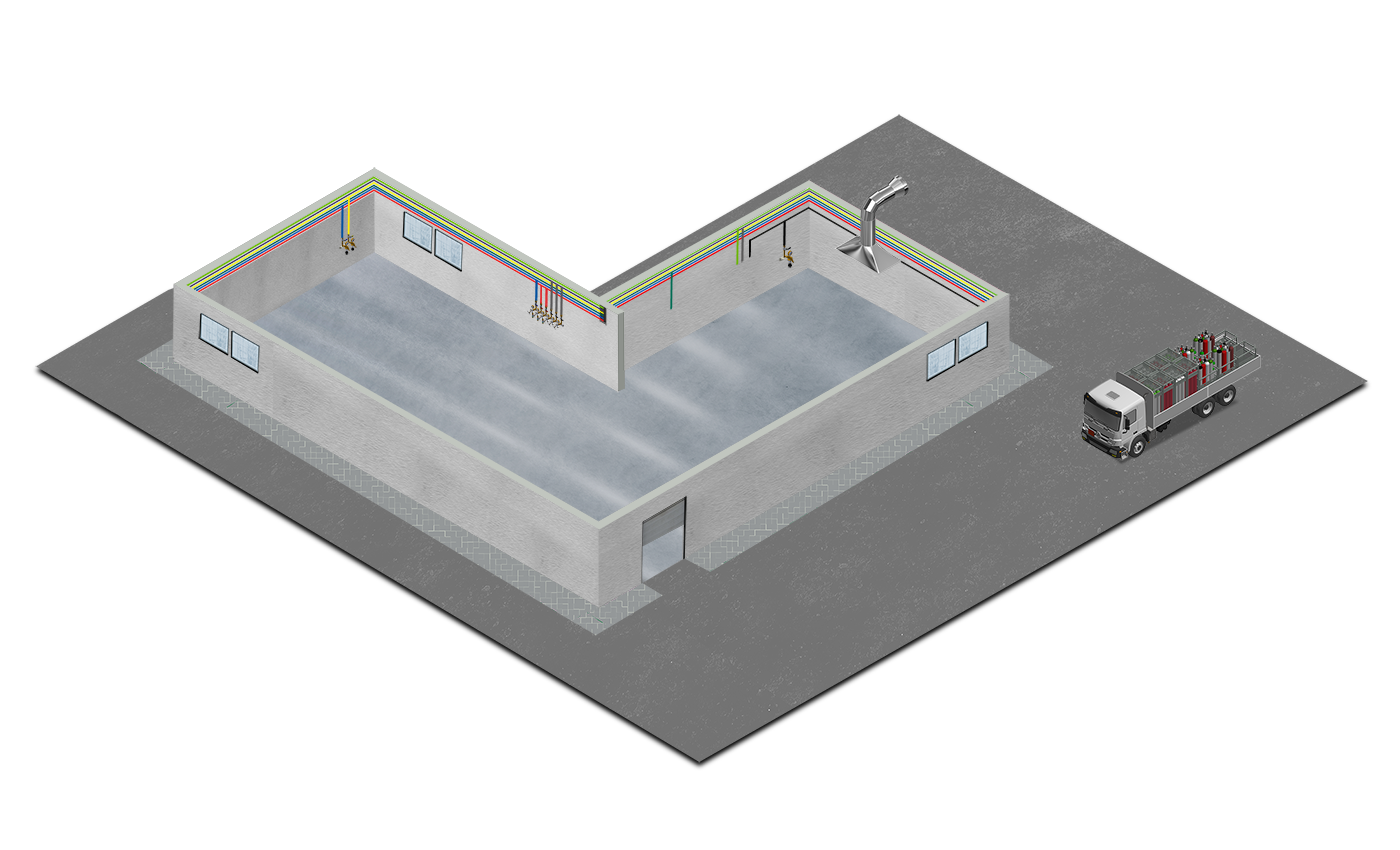

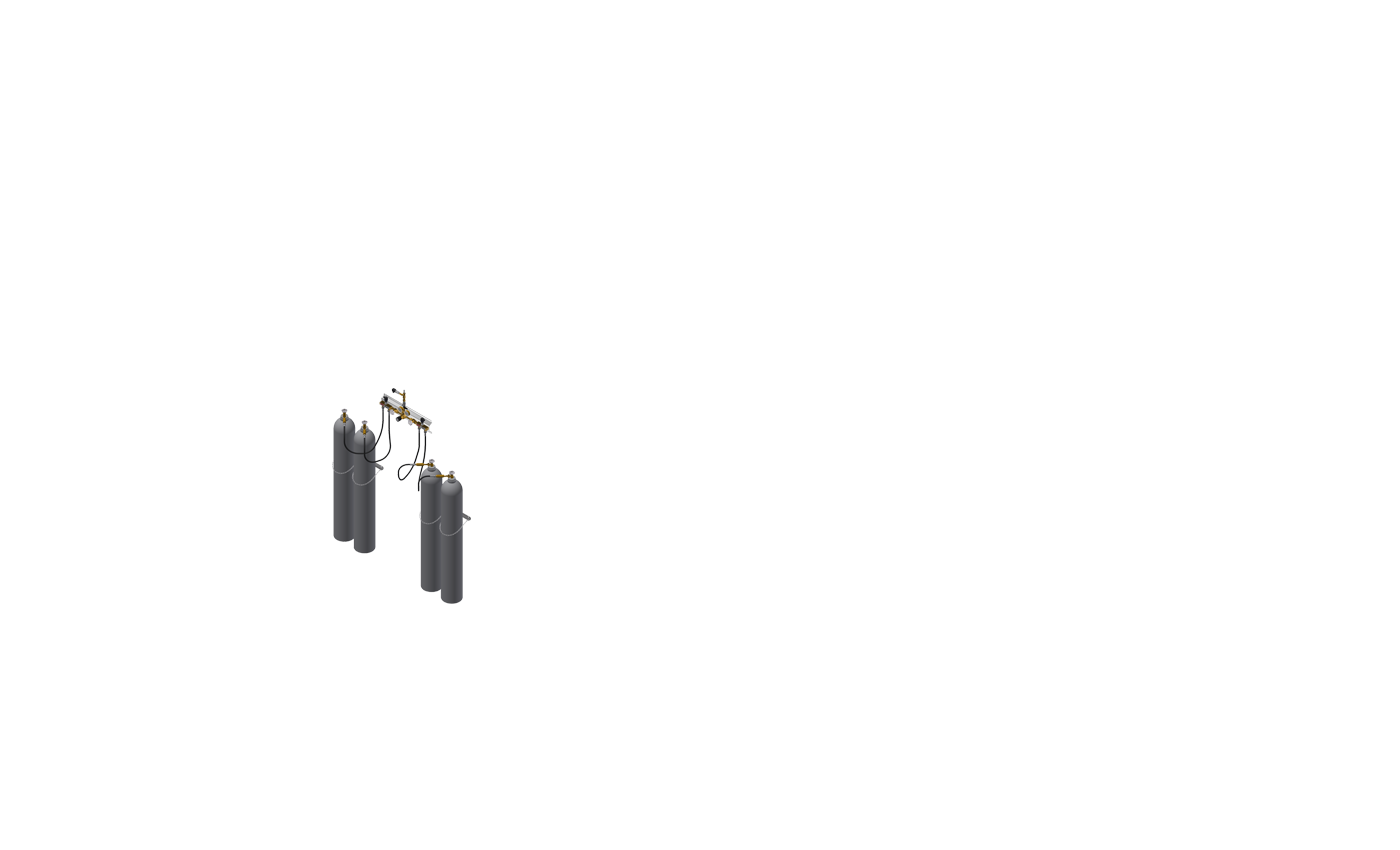

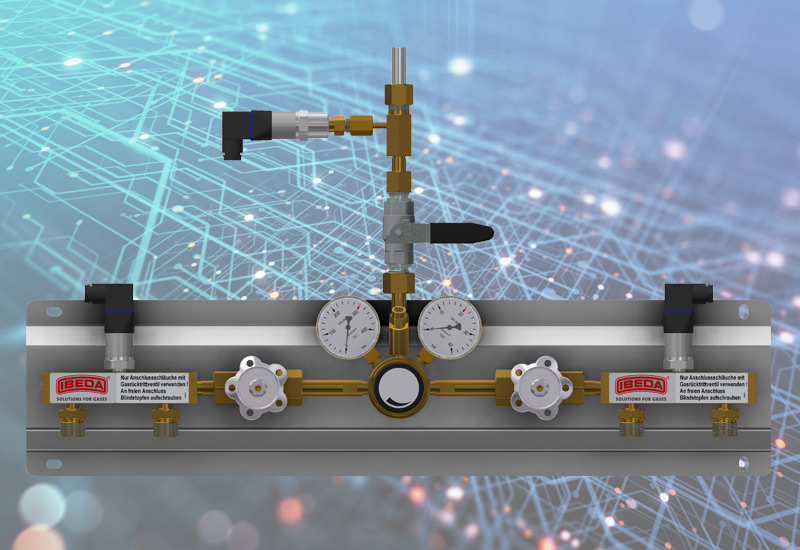

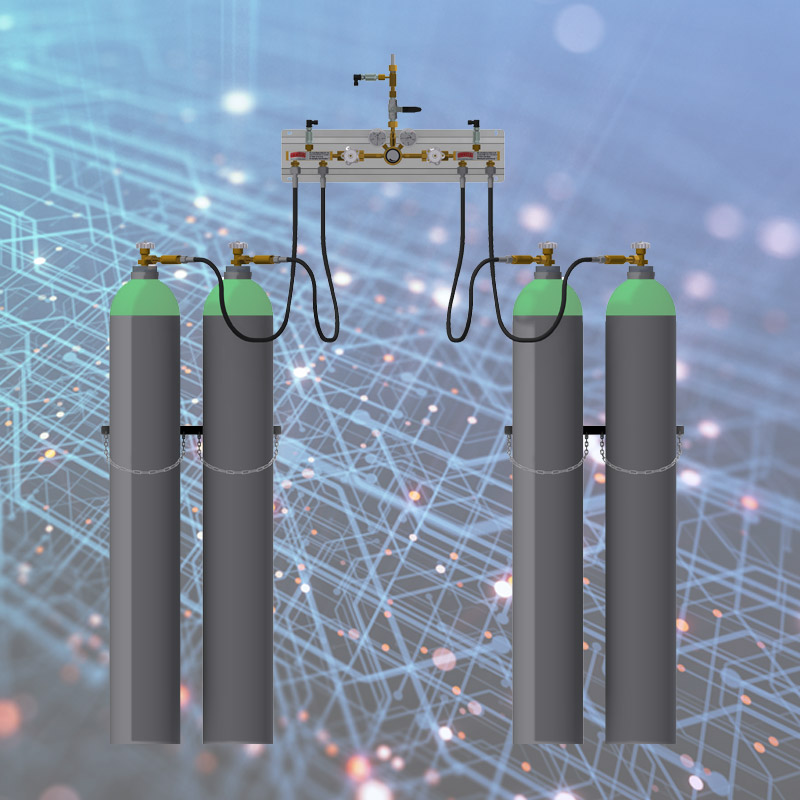

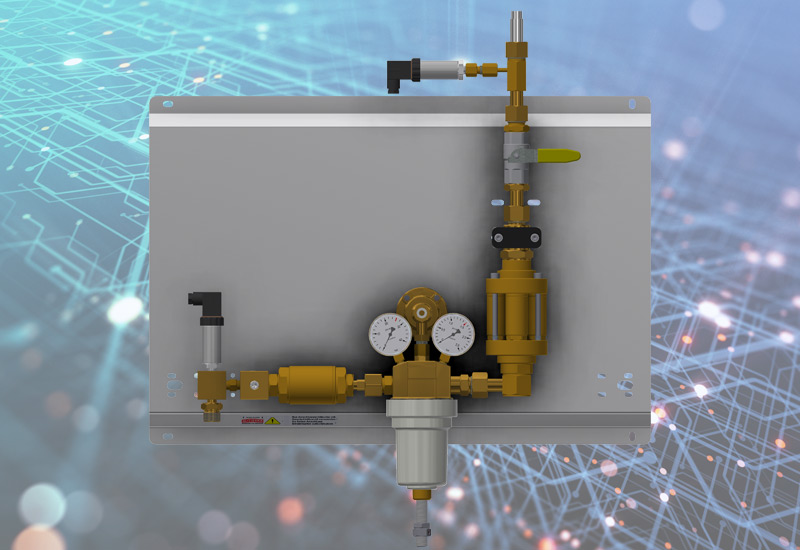

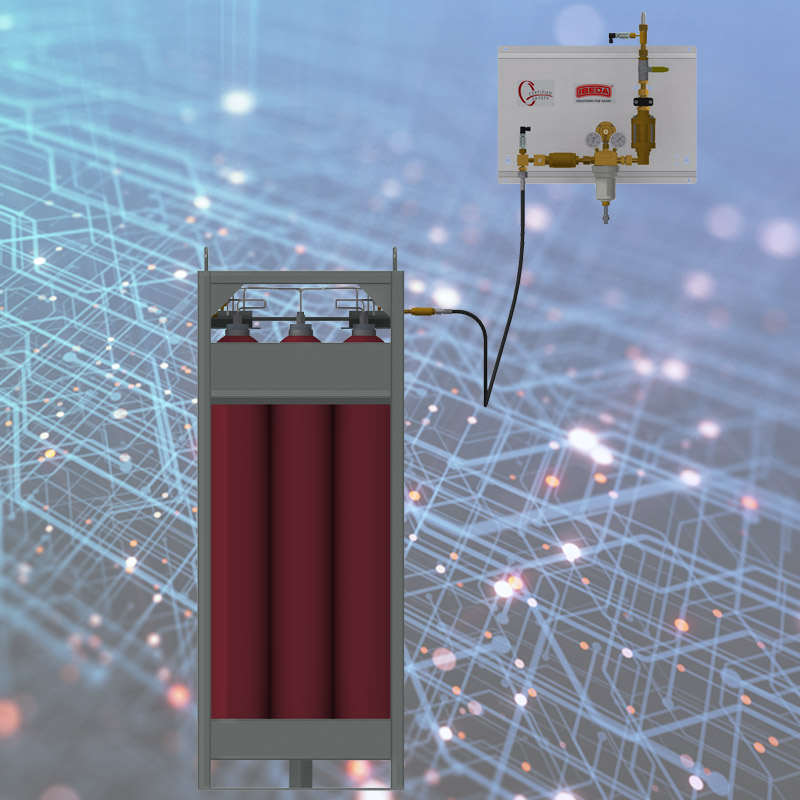

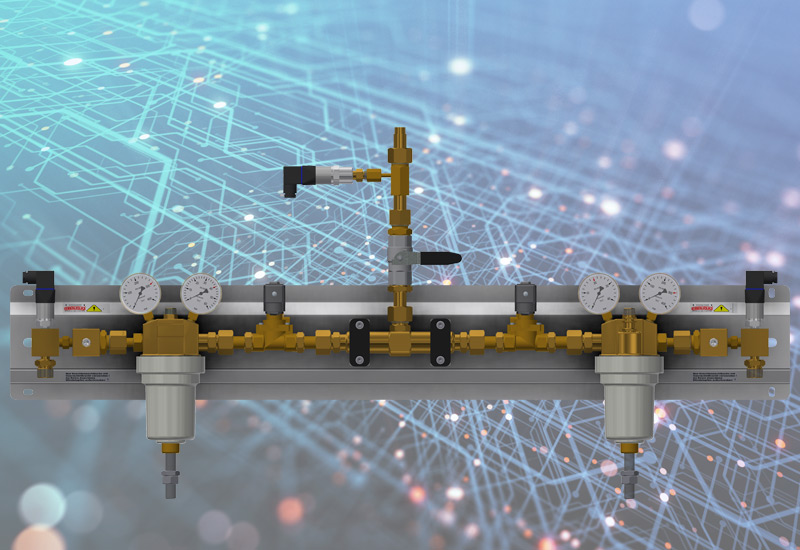

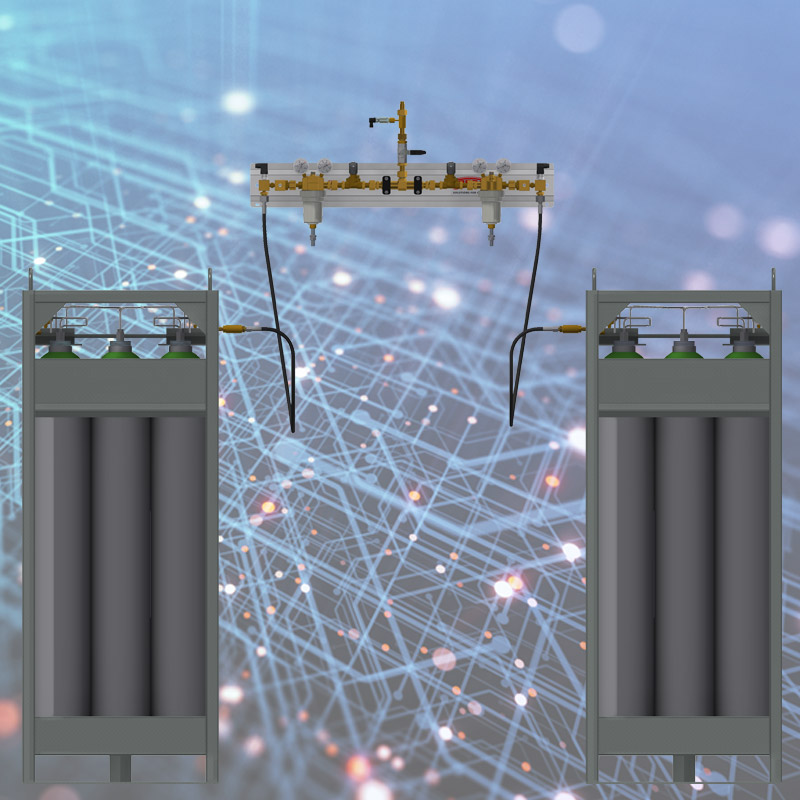

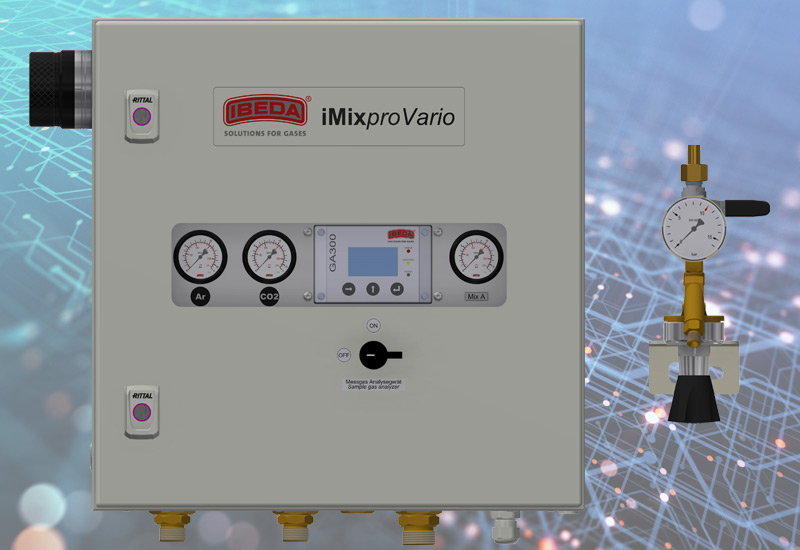

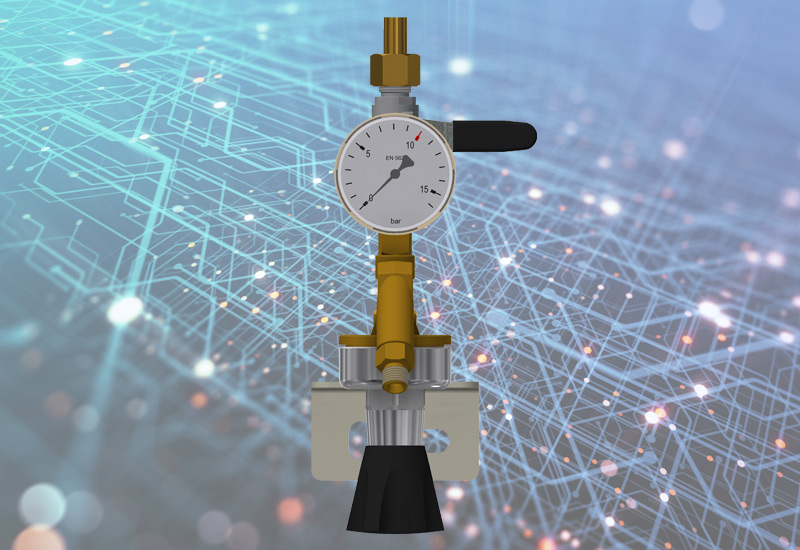

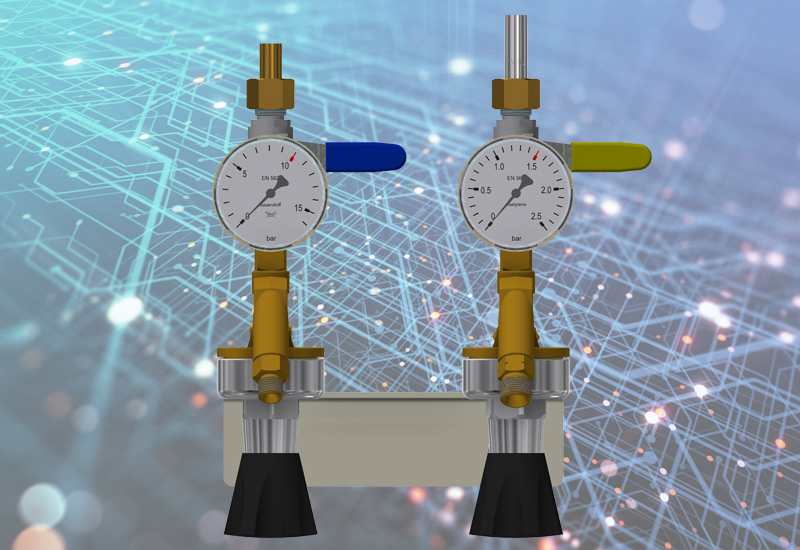

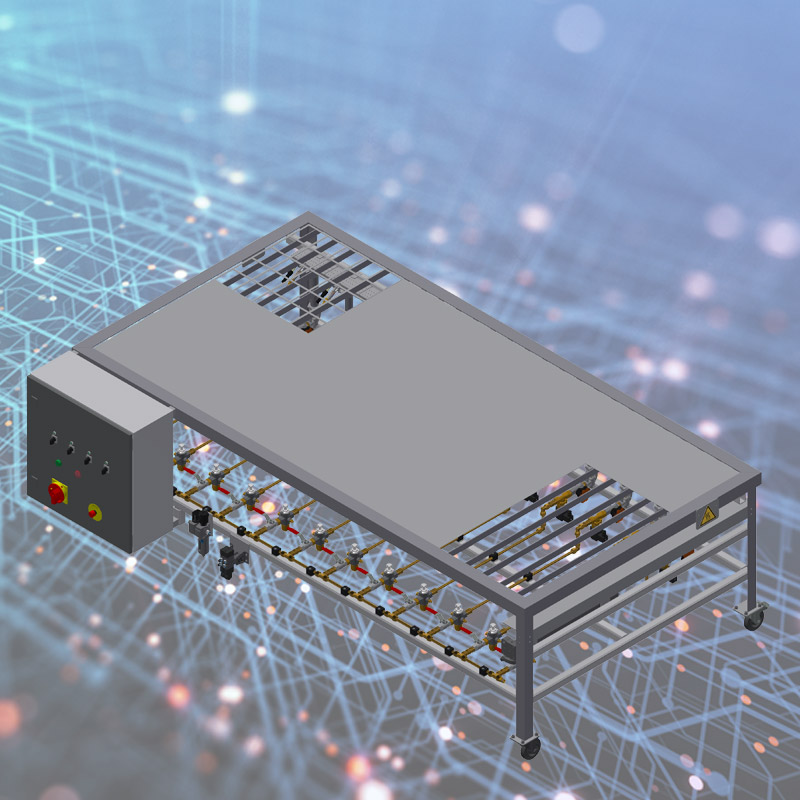

IBEDA gas manifold systems for oxygen and highly compressed gases are assembled ready for operation on stainless steel mounting plates. All safety-relevant components are BAM tested and certified. The consistent modular design of the individual assemblies ensures that the customer has a gas supply system that is optimally designed to meet his needs (without using of special parts). The modular system covers gas manifold systems with capacities up to 320 m³/h and cylinder/bundle pressures up to 300 bar.

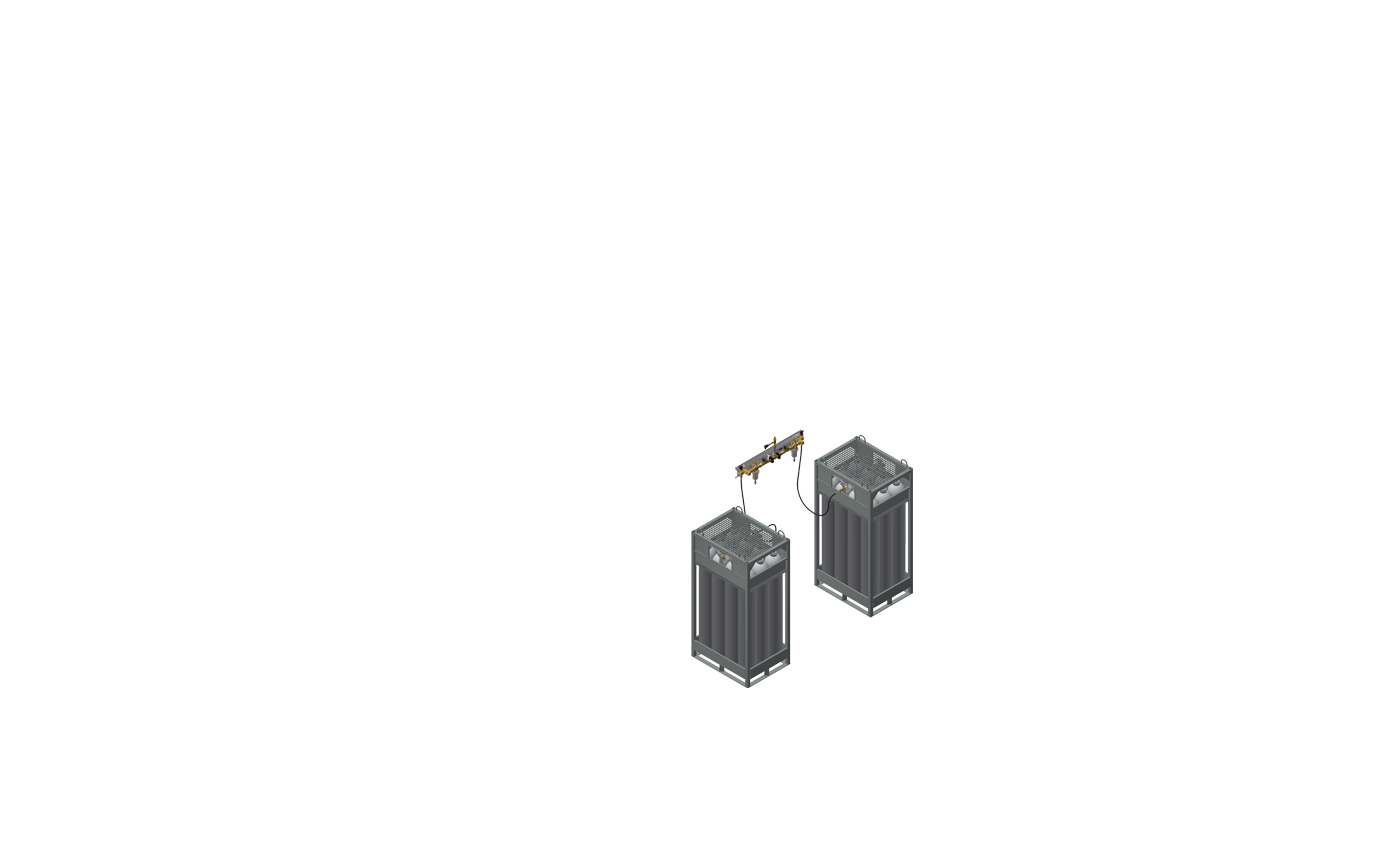

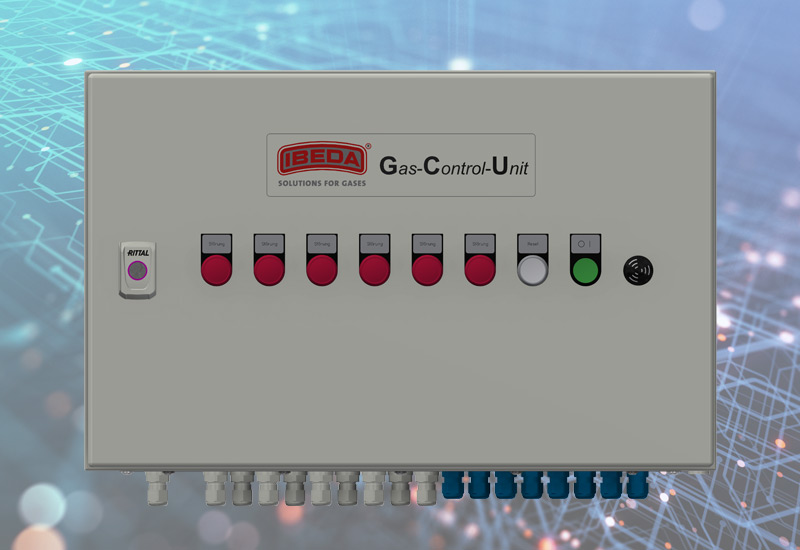

Data exchange

- The filling pressure of both gas sources is transmitted to the GCU by means of a pressure transmitter

- The minimum filling pressure of the gas sources is set in GCU

- The set line pressure is transmitted to the GCU by means of a pressure transmitter

- If the actual line pressure deviates from the set line pressure, a warning message is sent by the GCU

- If the filling pressure of the gas source falls below the set minimum, the GCU sends a message:

- An employee is notified (alarm message by e-mail) and can manually switch to the 2nd gas source

- The gas supplier receives a requisition note