Autogenous engineering

Custom heating solutions

FOR ALL REQUIREMENTS – FOR ALL INDUSTRIES!

No matter what requirements in heating engineering you have – IBEDA as a leading manufacturer focuses on a customized solution so you can focus on your production. Do you have new heating requirements or a current process in need of optimization? Let IBEDA assist you! IBEDA provides you with detailed advice, analyzes the issues, and develops a customized proposal. You will benefit from IBEDA's extensive experience with heating technologies as a manufacturer.

- more...

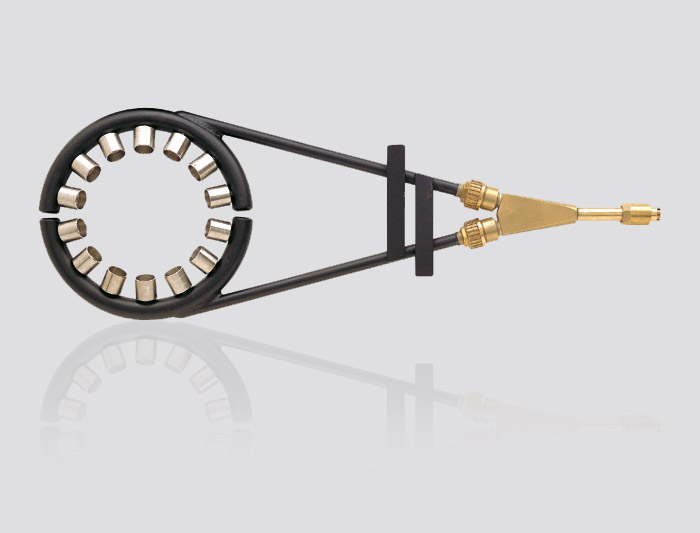

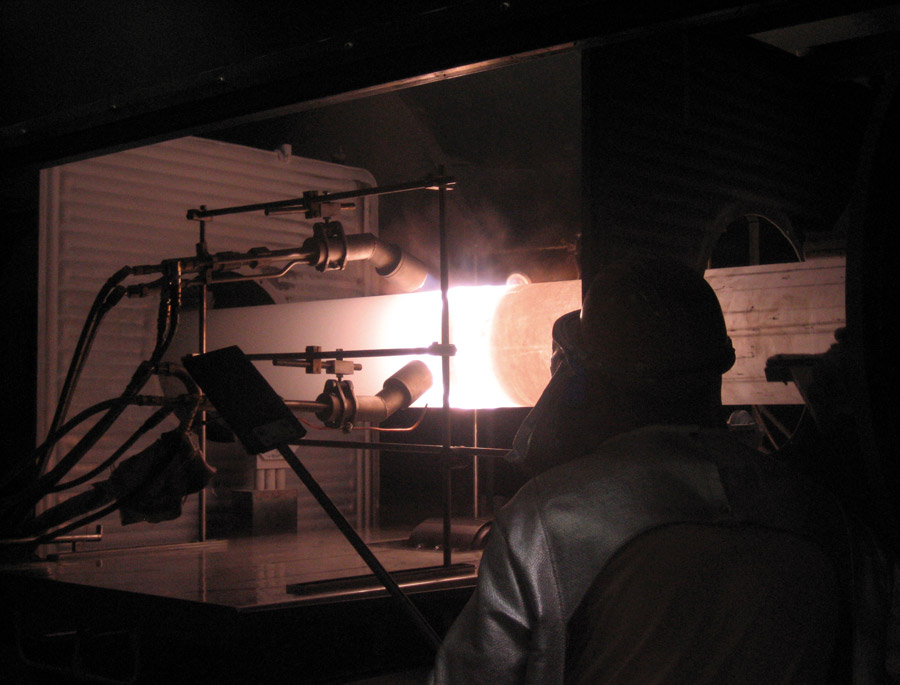

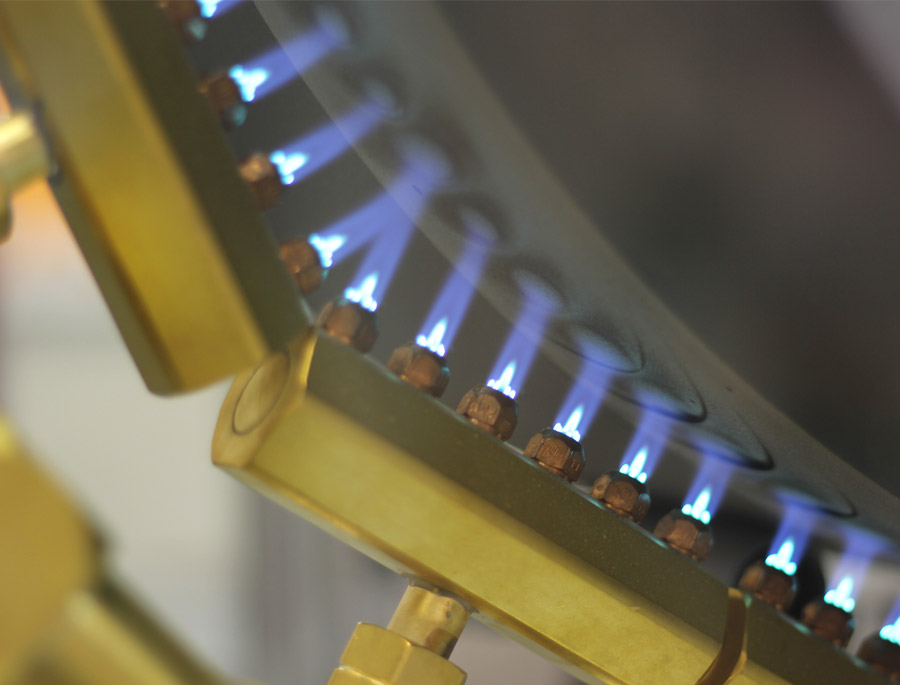

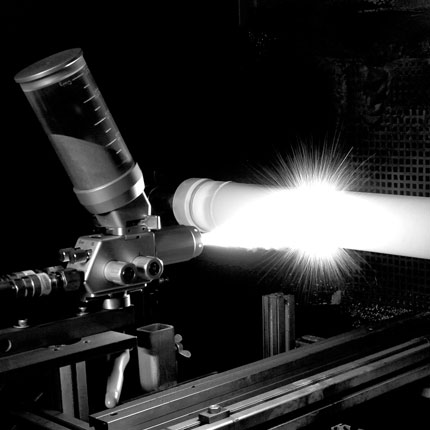

No matter if you need to work in preheating or hardening IBEDA offers heating burners for your application. The range of applications within IBEDA's heating engineering includes flame heating, flame hardening, flame cleaning, flame brazing and flame straightening. IBEDA supplies customized ring burners and standard burners such as: split ring burners (swivel ring burners), ring burners, ring burners and segment burners with burner controls and flame controls. Since taking over the Müller Opladen autogenous engineering and the Sirius heating technology IBEDA offers ring burners and swivel ring burners (split ring burner) with shaft connections suitable for Sirius and Müller products.

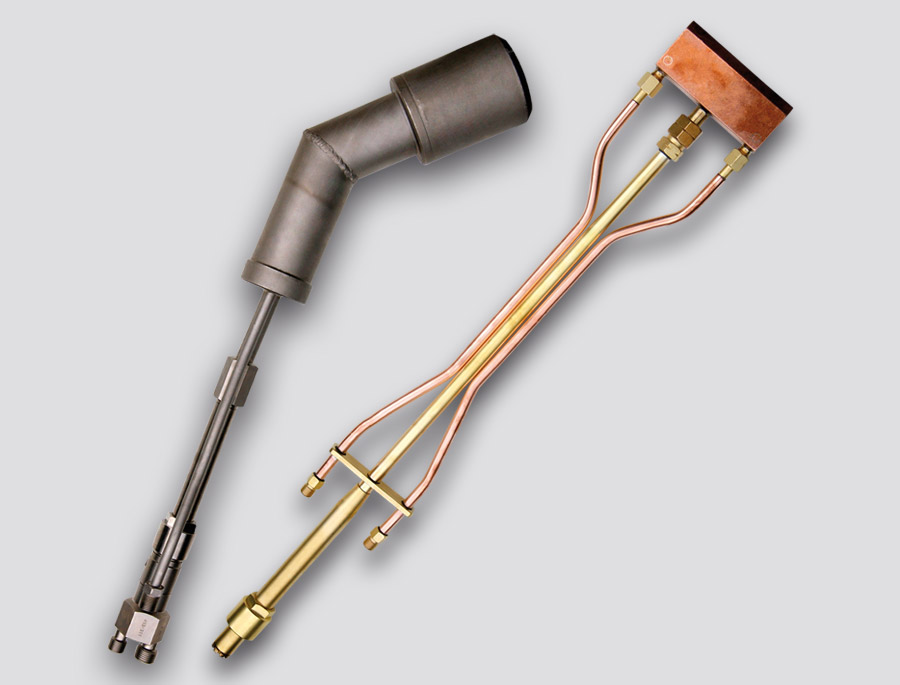

- Special autogenous burner systems

Individually developed special autogenous burner systems

IBEDA specialises in heating burner systems individually developed according to customer specifications. The scope of delivery includes conception, design, manufacture and commissioning of special burner systems. A risk analysis as well as an operating manual bring this comprehensive package to a full circle. We take advantage of components such as machine shafts, injectors, and heating nozzles that have been tried and tested and applied successfully for decades.

When it comes to safety, these systems are compliant with the latest state-of-the-art technologies and are fitted with all necessary safety devices. This includes safety, ignition, and flame monitoring equipment. The special burner systems can be offered for fuel gases such as acetylene, propane, and natural gas in combination with compressed air or oxygen.

We also offer gas supply panels (gas control paths) that ensure the sufficient supply of the heating burners with technical gases. The gas supply panels are fitted with all necessary safety devices. Special burner systems (heating burner systems) that are operated with fuel gases such as acetylene, propane, and natural gas in combination with compressed air, use additional EcoVen vacuum air injectors that reduce the required compressed air consumption by up to 75%.

- Custom solutions for heating engineering projects

No matter what heating technology requirements you have – we'll focus on a customized solution so you can focus on your production.

Do you have new heating requirements or a current process in need of optimization? Let us assist you! We'll provide you with detailed advice, analyze the issues, and develop a customized proposal.

You will benefit from our extensive experience with heating technologies.

IBEDA heating systems are designed in complete cooperation with the customer.

- From the inquiry, an offer is submitted based on the customer's specifications and requirements.

- Upon receipt of the customer's order, the special burner is designed/constructed and then approved by the customer.

- The operational manual is created.

- The burner system is completely assembled and approved by the manufacturer and the customer before delivery.

- Complete technical documentation is provided with the equipment.

- IBEDA offers support even after installation.