Gas manifold systems with automatic switch-over

Highlights

- Modular system

- Modules mounted on a plate

- Tested for strength, function and tightness before shipment

- Equipped with all design-type tested safety devices required

Technical data gas manifold systems

- Gas type: Acetylene, Oxygen and high-compressed, non-corrosive gases

- Inlet pressure: Acetylene 25 bar, other gases up to 300 bar

- Working pressure Acetylene: 0.6 to 1.5 bar (mechanical switch-over) or 0.6 to 1.35 bar (electrionic switch-over).

- Other gases: mechanical and pneumatic change-over 10 or 20 bar (pre-set), electronic change-over adjustable from 2 to 16 bar

- Flow rate: Acetylene 5 to 150 Nm3/h, Oxygen and high-compressed gases 60 to 320 Nm3/h

- Number of cylinders: up to 2 x 6 cylinders

- Bundles: Up to 2 x 12 bundles

- Assembly: Mounting plates made of stainless steel or plastic-coated steel. Optical and acoustic alarm. Design-type tested non-return valves with all cylinder- and bundle-connections.

Apart from the single-sided gas supply stations and the gas manifolds with manual switch-over, IBEDA supplies systems with automatic change-over ensuring the continuous gas supply. These automatic switch-over manifolds are suitable for Oxygen, for the fuel gases Acetylene, Hydrogen, Ethene, natural gas as well as for Nitrogen, Helium, CO2 and gas mixtures which are common for shielding gas welding (MIG/MAG, WIG), for example Argon/Helium and Argon/CO2. The IBEDA gas manifold systems with automatic change-over unit are suitable for inlet pressures up to 25 bar Acetylene or 300 bar Oxygen and other technical gases, supplied from cylinders or bundles.

The IBEDA gas manifolds systems with mechanical or pneumatic change-over unit are supplied with contact gauge and alarm device which optically and acoustically indicates the need to change the cylinder or the bundle once the manifold switched-over. The pneumatic change-over manifold is not available for Acetylene. The automatic manifold system with electrical switch-over unit is working with solenoid valves where the change-over pressure can be adjusted at the contact gauge.

The automatic gas supply stations for Acetylene meet the safety related requirements as per the standard DIN EN 14114. So they include an automatic quick-action shut-off valve downstream the regulator and a safety devices according to EN ISO 5175-1 (decomposition arrestor) at the outlet of the pressure regulator.

Details - Gas manifold systems with automatic switch-over

Gas manifold centre

Gas manifold centre

The gas manifold centre of a company producing gearboxes in Württemberg/Germany.

Gas manifold for tempering steel

Gas manifold for tempering steel

Gas manifold for acetylene with an automatic changeover for 2x3 MCPs to supply a tempering oven.

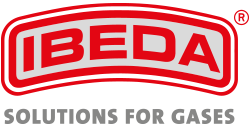

Electronically controlled auto-change manifolds for Oxygen

Electronically controlled auto-change manifolds for Oxygen

Electronically controlled gas manifold for technical non-corrosive gases. These systems are rated for all inlet pressures ranges up to 300 bar. Pressure switches makes it possible to adjust to an exact changing pressure, therefore a continuous, uninterrupted supply is ensured. Instead of MCPs it is also possible to use one or more single cylinders.

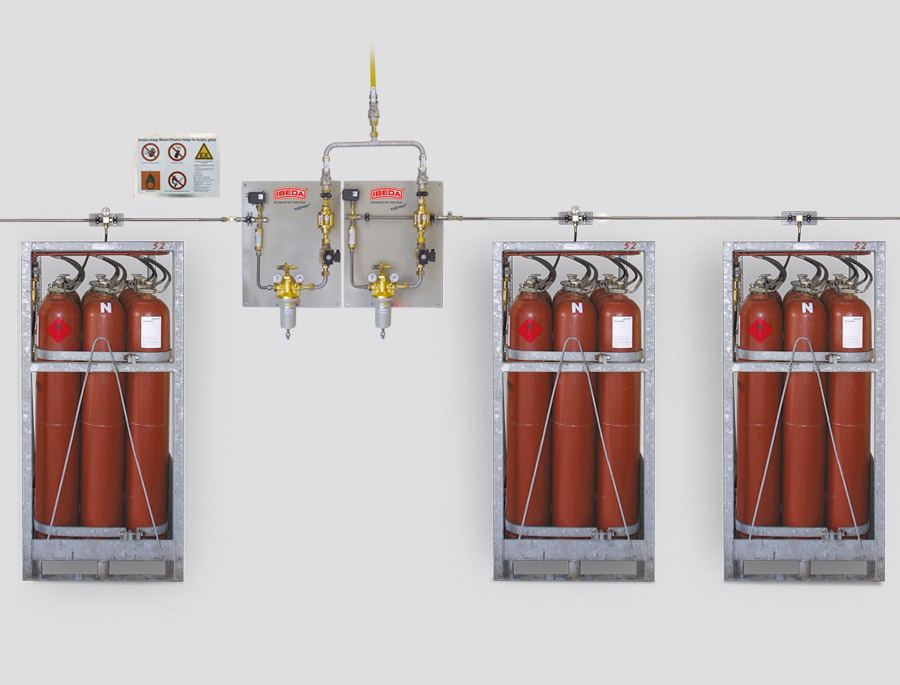

Pneumatically controlled auto-change manifolds for Oxygen

Pneumatically controlled auto-change manifolds for Oxygen

IBEDA pneumatically controlled auto change manifold for oxygen and technical gases. This gas manifold is pre-adjusted to a defined working pressure. The pneumatical pre-assembled unit changes at a differential pressure of 3 bar. A contact gauge can be incorporated to show cylinder status.

Electronically controlled auto-change manifolds for acetylene

Electronically controlled auto-change manifolds for acetylene

The picture shows an electronically controlled auto-change gas manifold for Acetylene MCPs (up to flow of 150 Nm3/h).This is equipped with explosion prooved solenoid valves which guarantee continuous supply to the connected consumers. The pressure switches makes it possible to choose the exact changing pressure. The control signal can be sent to an alarm panel either with an optical and an acoustic alarm indicating when MCPs need to be changed.