IBEDA Gas manifold systems

for technical gases

Gas manifolds, tapping points and gas distributors

IBEDA as a manufacturer supplies gas manifolds for various fuel gases such as Acetylene (according to EN 14114), Hydrogen, Methane and Propane as well as for Oxygen and other high pressure compressed technical gases such as Nitrogen, Argon and CO2. The individual components of the Oxygen supply systems are all tested for Oxygen burnout. From the high pressure connection hose (according to EN 14113), collection pipe with high pressure non-return valves (check valves) to flashback arresters (according to EN 15615) IBEDA offers our gas manifold systems in stationary and mobile designs.

- more...

The gas manifolds are also available with options such as gas pre-heaters and gas filters. Tapping points can be supplied in a stationary design with tapping point regulator and flashback arresters or alternatively as a mobile unit such as a mobile tapping point. These are available with options including tapping point regulators, flashback arresters and quick-action couplings (EN 561). The manufacturer IBEDA offers an extensive accessory program such as gas pre-heaters and gas filters for example.

Central gas supply

for all points of use

Printversion IBEDA Gas manifold systems

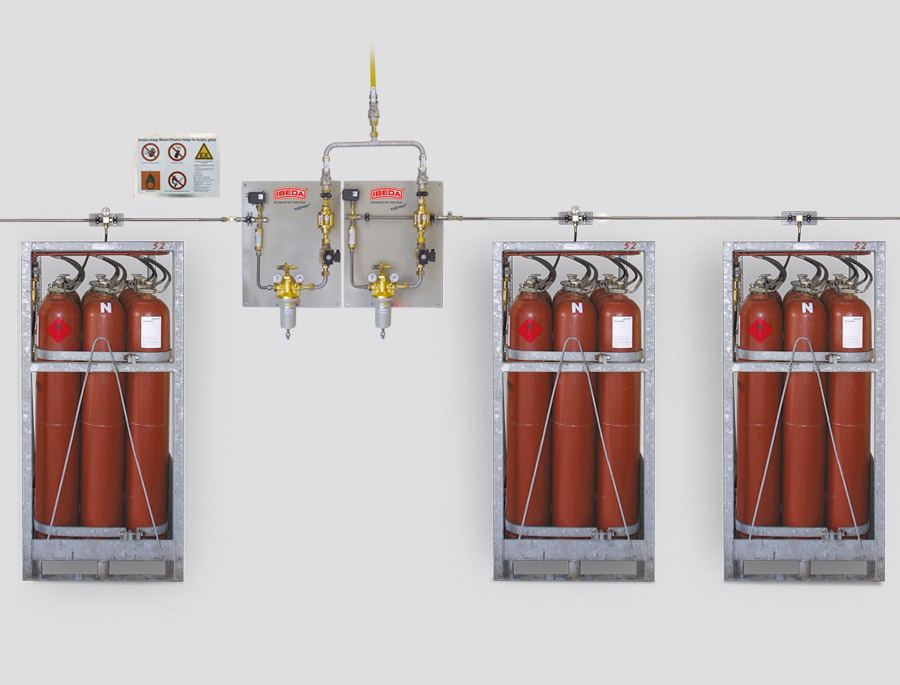

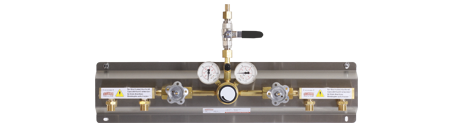

1Gas manifold 2x2 cylinders Nitrogen

Type: GMS-DV-BT-300/20-2x2

IBEDA gas manifolds for Acetylene comply with DIN EN 14114 and TRAC 204, 206 and 208. They are mounted on a stainless steel plate and are BAM tested and approved. The modular design provides highest flexibility in installation and ensures to meet the customer‘s requirement. The whole capacity range up to 1503 m3/h can be covered by this modular concept.

2Gas manifold 2x2 bundles Acetylene

Type: GMS-BKH-SSE-U13-25/1,5-SIMAX3-2x1

IBEDA gas manifolds for Acetylene comply with DIN EN 14114 and TRAC 204, 206 and 208. They are mounted on a stainless steel plate and are BAM tested and approved. The modular design provides highest flexibility in installation and ensures to meet the customer‘s requirement. The whole capacity range up to 1503 m3/h can be covered by this modular concept.

3Gas manifold 2x2 cylinders Argon

Type: GMS-DV-BT-300/20-2x2

IBEDA gas manifolds for Oxygen and technical gases are mounted on stainless steel plates. All safety-relevant components are BAM tested and approved. The modular design provides highest flexibility in installation and ensures to meet the customer‘s requirement. The whole capacity range up to 3203 m3/h and cylinder or bundle pressures up to 300 bar can be covered by the modular concept.

4Mobile gas manifold

single cylinder Acetylene incl. hanger

Type: GMS-SSE-U13-25/1,5-SIMAX3-1x1

IBEDA mobile gas manifolds offer custom solutions for mobile gas supply. All inherent safety devices comply with DIN EN 14114. The hanger ensures the secure mounting of the gas manifold at the MCP rack.

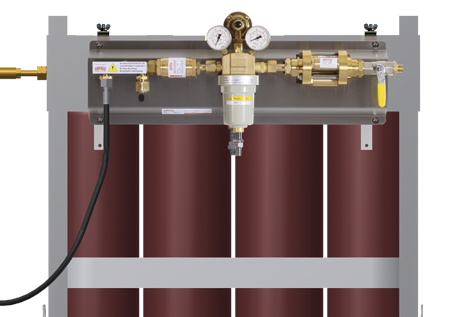

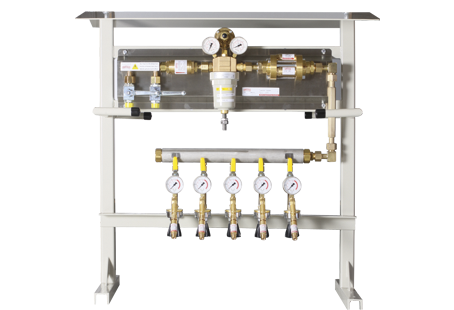

5Mobile gas manifolds 2x1 bundles Acetylene

for gas supply on-site incl. tapping points

Type: TGMS-BKH-SSE-U13-25/1,5-SIMAX-2x1-GEV5

IBEDA mobile gas manifolds with integrated tapping points offer custom solutions for mobile gas supply. Up to six workstations can be supplied simultaneously from two MCPs. All inherent safety devices comply with DIN EN 14114.

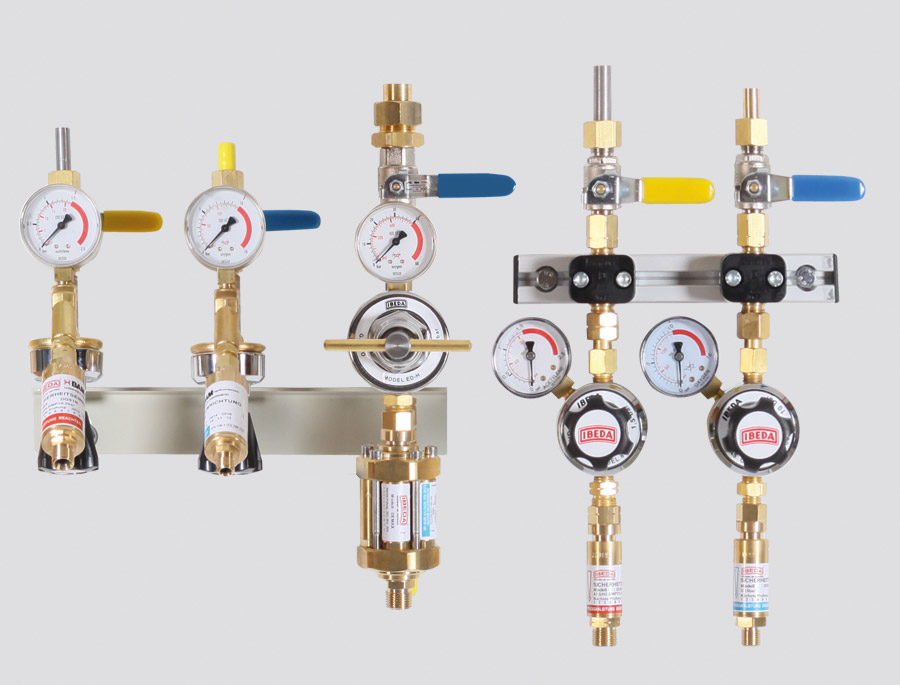

6Tapping point for heating burners

Type: E10

IBEDA supplies tapping points for the gas supply, matched to the gas type, the working pressure and the flow rate. Operating pressures for Acetylene up to 2.5 bar and Oxygen or technical gases up to 60 bar. Flow rates up to 200 m3/h are standard. Customised solutions can be offered.

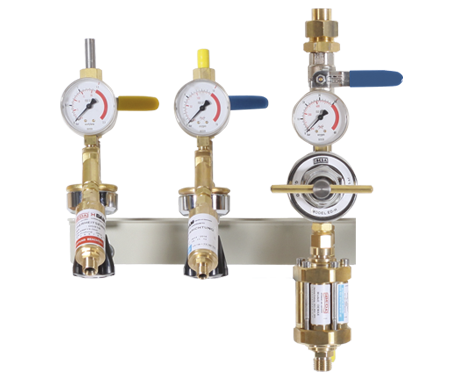

7iMixpro

Gas mixer with integrated constant pressure regulators and auto-stop function

The iMixpro gas mixer operates according to the diffusion mixing principle. It has an integrated constant pressure regulation and features an auto-stop function stopping the production of the gas mixture when the gas supply is interrupted.

The iMixpro gas mixer can be used for the simultaneous production of up to two pre-defined and pre-adjusted gas mixtures of two gases. Additionally, there is an iMixpro version available allowing the production of a pre-defined and pre-set gas mixture of three gases. The inlet pressures of the gases to be mixed and the outlet pressure of the gas mixture are indicated by the integrated pressure gauges.

Due to the diffusion mixing principle, the iMixpro guarantees a constant gas mixture even in case of gas withdrawal variations and without additional buffer vessel.

Optionally, the iMixpro can be equipped with inlet and outlet pressure regulators for setting the required mixture pressure. In addition, a gas analysis for process control can be integrated in the mixer housing on request.

Thanks to the pre-set and fixed gas mixtures calibrated to the respective requirements, an accidental change of the mixtures is impossible. This makes the iMixpro gas mixer perfect for applications where a constant mixing ratio is absolutely necessary.

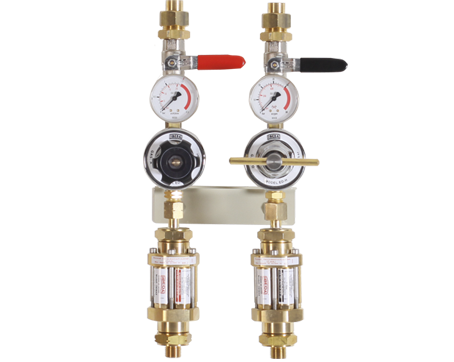

8Tapping points for welding machines

Type: E1

IBEDA supplies tapping points for the gas supply, matched to the gas type, the working pressure and the flow rate. Operating pressures for Acetylene up to 2.5 bar and Oxygen or technical gases up to 60 bar. Flow rates up to 200 m3/h are standard. Customised solutions can be offered.

9Tapping points for cutting machines

Type: E1 and E10

IBEDA supplies tapping points for the gas supply, matched to the gas type, the working pressure and the flow rate. Operating pressures for Acetylene up to 2.5 bar and Oxygen or technical gases up to 60 bar. Flow rates up to 200 m3/h are standard. Customised solutions can be offered.

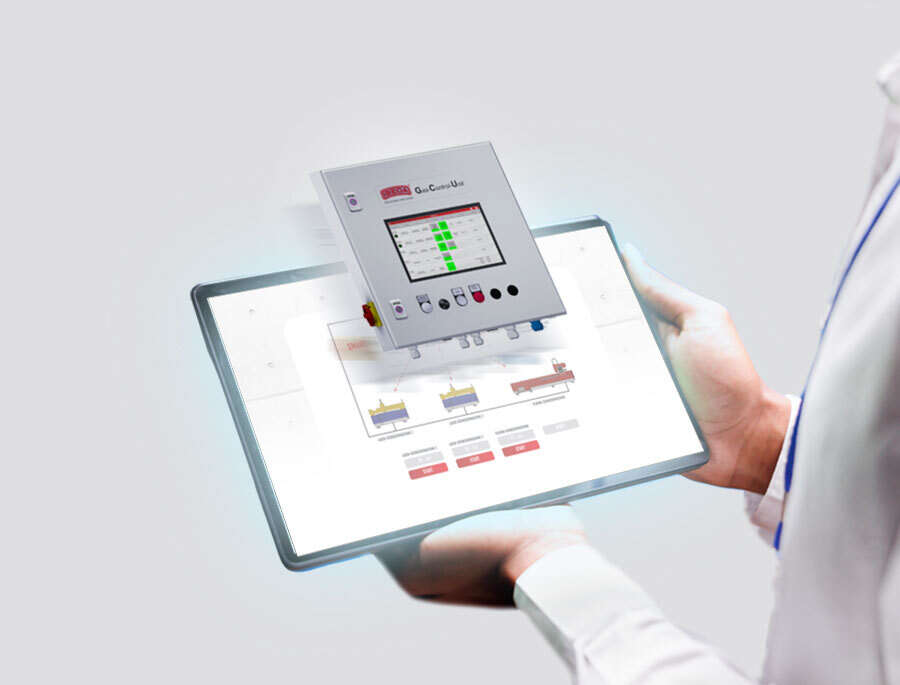

10Gas Control Unit (GCU)

for controlling and monitoring of gas manifold systems

With the IBEDA Gas Control Unit (GCU) for the control and monitoring of gas manifold systems, the uninterrupted supply of the manufacturing processes can be ensured. The supply is achieved by automatic, semi-automatic or also by manual changeover systems.

11Tapping point Nitrogen for testing unit PV-GD

Type: E1

IBEDA supplies tapping points for the gas supply, matched to the gas type, the working pressure and the flow rate. Operating pressures for Acetylene up to 2.5 bar and Oxygen or technical gases up to 60 bar. Flow rates up to 200 m3/h are standard. Customised solutions can be offered.

The IBEDA gas manifolds ensure the continuous supply of technical gases from the gas cylinder or bundle to the point of use. Additionally, we supply all components for mobile and stationary manifolds, such as high-pressure non-return valves, gas stations, tapping points, gas mixers, safety devices and accessories. All safety-relevant components are BAM tested and approved. Due to the modular concept, the gas manifold station can easily be extended to meet the customer's requirement.