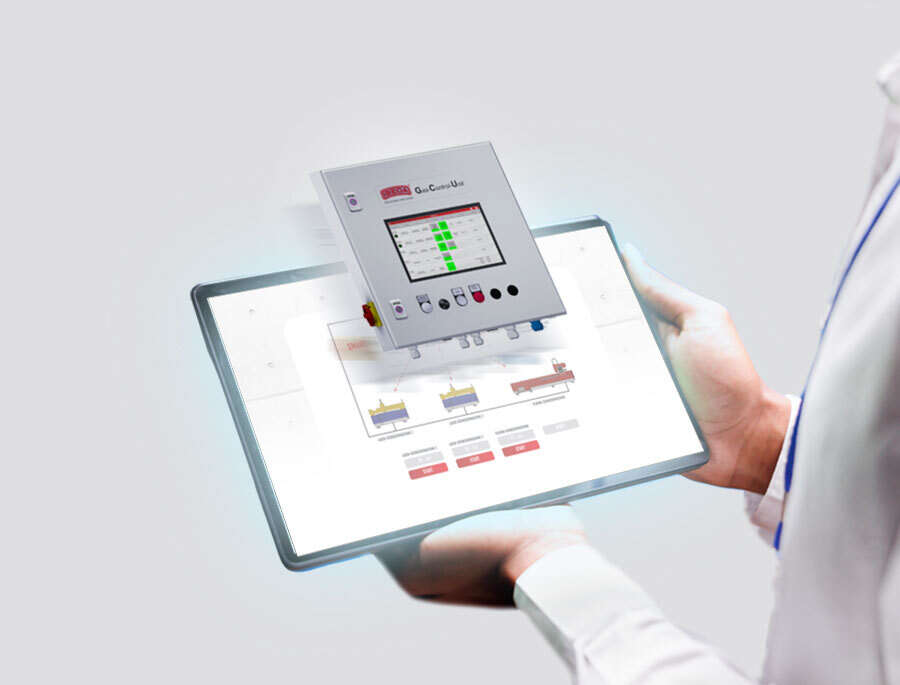

Gas Control Unit (GCU)

for controlling and monitoring of gas manifold systems

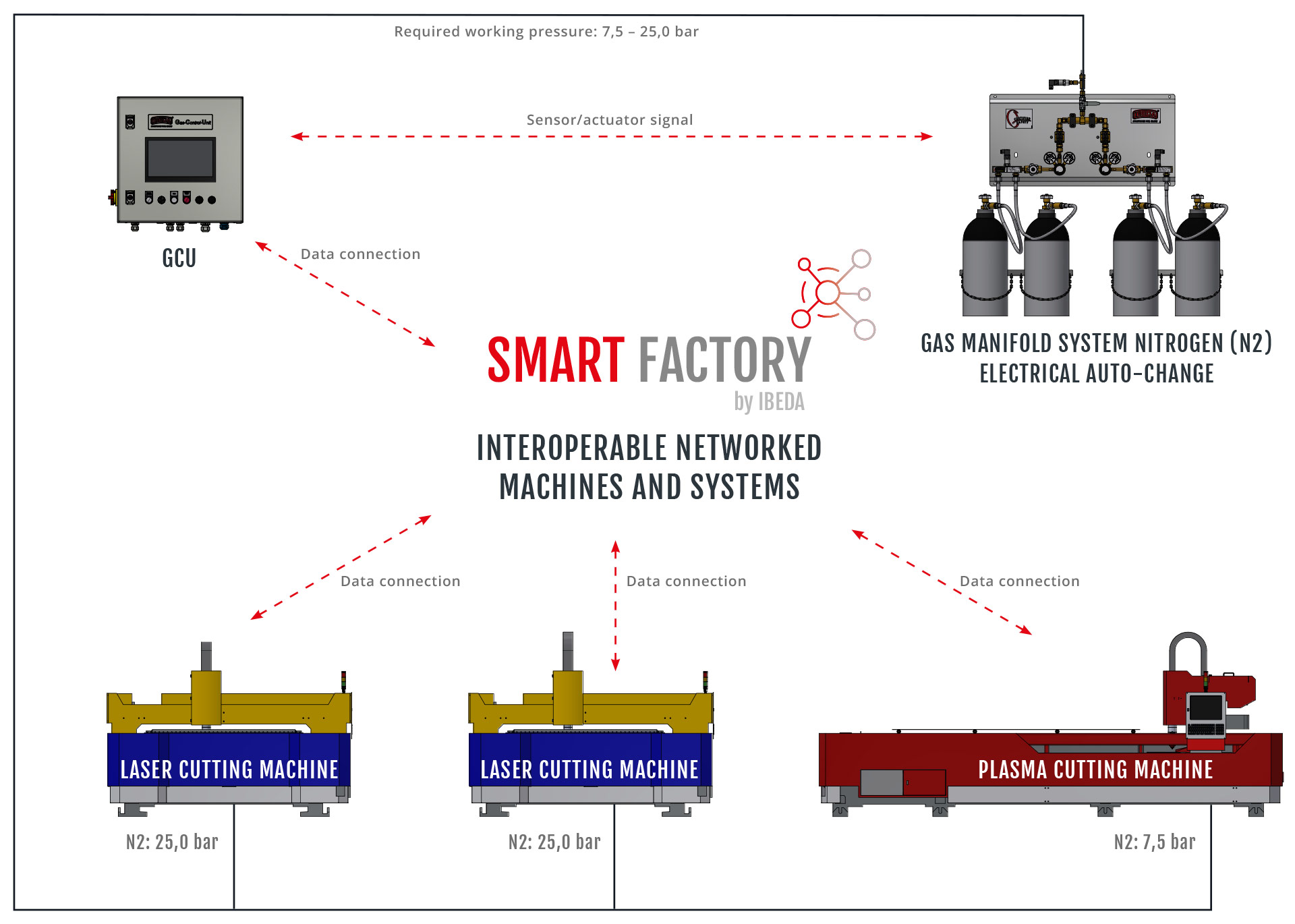

When talking about an uninterruptible gas supply with technical gases, the entire process from the gas supplier to the application has to be considered. With the IBEDA Gas Control Unit (GCU) for the control and monitoring of gas manifold systems, the uninterrupted supply of the manufacturing processes can be ensured. The supply is achieved by automatic, semi-automatic or also by manual changeover systems. The digitalization and networking of gas supply systems in the Smart Factory in the sense of Industry 4.0/ IIoT offers decisive advantages for ensuring the supply of gases and creating corresponding added value, such as gas savings and the highest possible process reliability. In addition, networking with other production systems, such as flame cutting machines or heating systems, provides further advantages in automation and in the optimization of production processes.

Highlights

- Future-proof through MQTT and OPC-UA interface, a standard for data exchange as a platform-independent and service-oriented architecture

- Simple and intelligent communication with networked machines and systems

- Control of auto-change gas manifolds for uninterrupted gas supply

- Monitoring of mechanical and semi-automatic gas manifold systems

- Easy integration and monitoring of existing systems RETROFIT

- Optimal use of gas resources with regeneration of the gas source

- Reduction of stock of gas and rented gas cylinders through monitoring

- Providing and recording information on pressure and filling level

- Leakage check of the supply lines and high-pressure collection pipes

- Function control of the pressure regulators, prevention of unintentional release of the safety valves

- Reminder of due maintenance of the gas supply systems

- Clear messages and warnings by email

- WEB browser-based operation and display

- LAN connection to the corporate network

- Adjustable pressure and volume

- Multilingual navigation

Use in explosive areas

- The GCU must always be installed outside the potentially explosive area.

- Alarm devices (pressure transmitters) installed within a potentially explosive atmosphere must be controlled via an ATEX- approved switch amplifier.

- When ordering, it must therefore be indicated how many gas manifold systems are operated in the explosion protection area.

- The appropriate numbers of switch amplifiers are integrated into the GCU then.