Eco-Ven Vaccum Air Injector

In the field of heating engineering, there is a wide range of applications for fuel gas/compressed air burners

Like heating paths for the glass industry, heating units at cutting machines, plate driers at steel plants, heating burners for die forging or heating of welded seams on large diameter pipes. For the combustion of fuel gas, the compressed air requirement is typically 4 to 15 times the requirement of fuel gas (depending on the gas type).

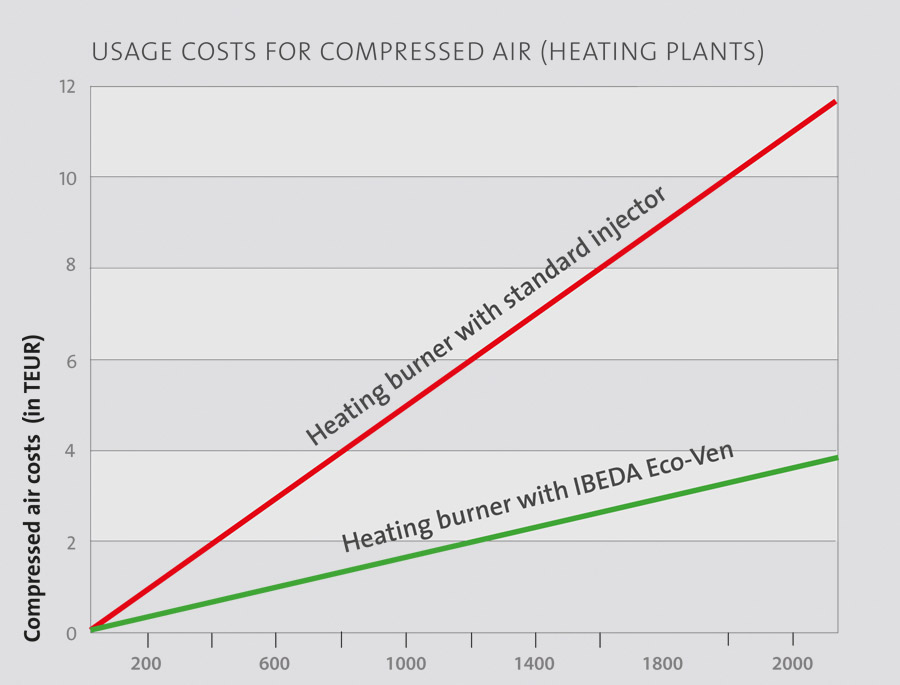

The production of compressed air is energy intensive and expensive (about 0,01 €/m3). This is the main reason for the development of the new IBEDA Eco-Ven. The Eco-Ven has been designed for both manual and machine guided burner applications. The new injector Eco-Ven provides a very high savings potential.

75% of the required combustion air is taken from the ambient atmosphere and only the remaining 25% of the combustion air is required from compressed air.

Save 75% of your compressed air expenses. This means cost savings along with conservation of natural resources!

Technical Data:

| Threads | Consumption | |||

| Type | Fuel Gas | Air | Vacuum air | Compressed air |

| Eco-Ven - 10 | G3/8-F | G1/4-F | 60 m³/h | 20 m³/h |

| Eco-Ven - 15 | G1/2-F | G1/4-F | 150 m³/h | 50 m³/h |

| Eco-Ven - 20 | G3/4-F | G3/8-F | 300 m³/h | 100 m³/h |

| Eco-Ven - 25 | G1-F | G1/2-F | 450 m³/h | 150 m³/h |

| Gas pressure: | > 50 mbar | |||

| Compressed air: | 0,2 to 0,5 MPa | |||

Applications:

Heating applications with fuel gas/compressed air mixtures. Valve injectors cover the range from 60m³/h to 600m³/h air. The Eco-Ven is applicable for fuel gas/compressed air burners.

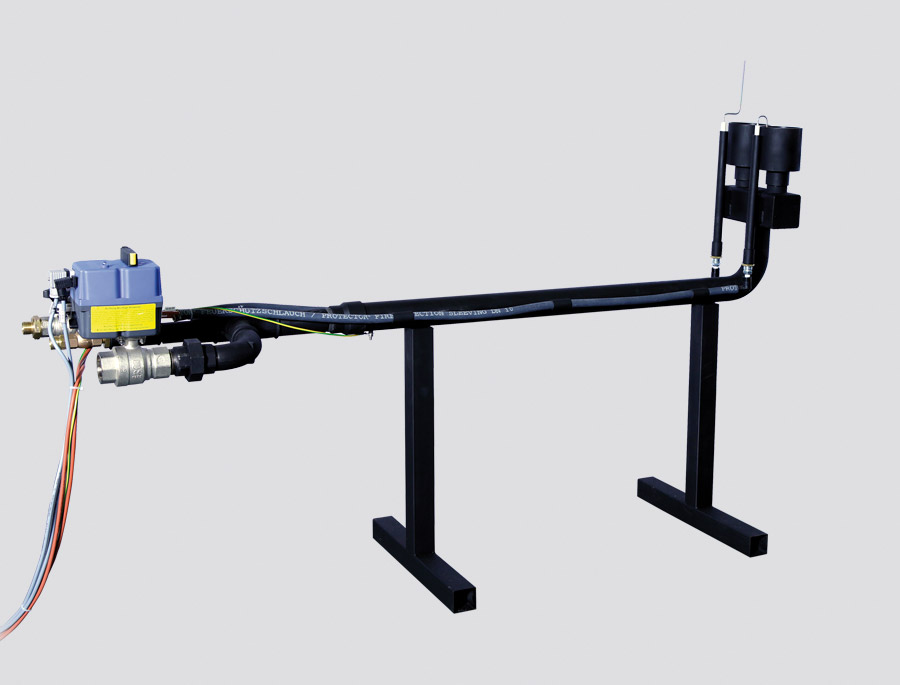

Initially the Eco-Ven works just like a standard product. Compressed air is fed and the fuel gas is supplied as well. Next, the burner has to be ignited. The Eco-Ven is equipped with an air inlet which can be engaged and the flame can be adjusted then.

Details - Eco-Ven

Usage costs for compressed air

Eco-Ven

Special Burners