Production flashback test of safety devices

conforming to EN ISO 5175-1

A production flashback test is to be carried out after manufacture on all safety devices conforming to EN ISO 5175-1. The gas mixture and the pressure for testing the flashback arrestors depend on the gas application and the maximum operating pressure.

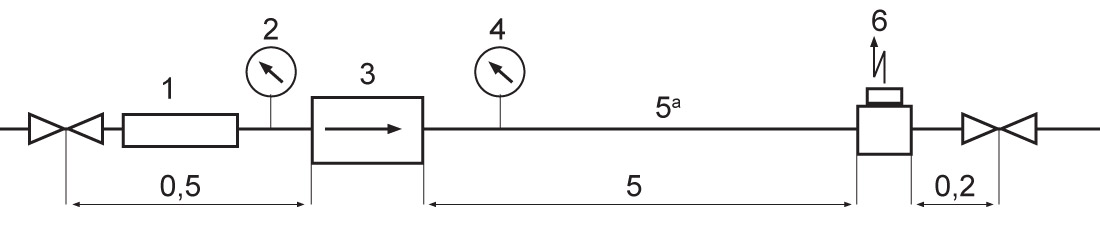

This diagram shows the set-up of the test equipment:

1 - Flame detector

2 - Inlet pressure p1

3 - Sample

4 - Outlet pressure p2

5 - Steel tube

6 - Ignition

For connections up to G3/8, a steel tube with an internal diameter of 10 mm shall be used. For connections larger than G3/8, the steel tube shall be equal to the nominal outlet bore of the safety device.

| Gas type |

Test pressure | Test mixture volume fraction in % of fuel gas in oxygen |

| Acetylene Oxygen Air |

1.5 bar | 32% to 35% Acetylene |

| LPG | maxiumum operating pressure | 13% to 15% Propane |

| Hydrogen | maxiumum operating pressure | 40% to 50% Hydrogen |

| other fuel gases | maxiumum operating pressure | 80% to 90% of stoichiometric mixture |

The test pressure, the gas mixture and the inner diameter of the steel tube are the decisive factors for the flashback test. The flashback test on the single safety device has to be done on the basis of the intended use of the unit. That means that only especially designed and tested safety devices are to be used for applications requiring higher working pressures or larger inner diameters of the steel tube.

Besides the BAM as an independent institute, IBEDA is able to carry out such flashback tests.