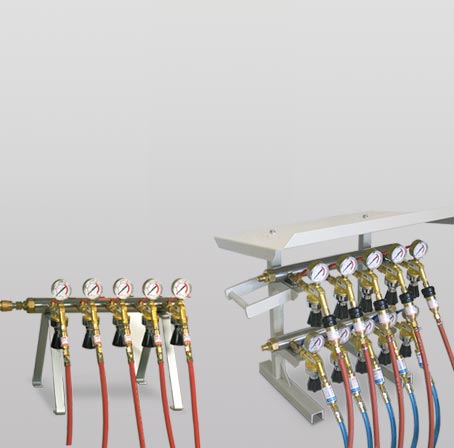

Mobile gas manifolds and tapping points

Highlights

- Gas supply according to the customer’s requirement

- Maximum safety on-site

- Easy to maintain

- Ready for immediate use

- Gas non-return valve up to 300 bar

- Coming with safety devices meeting all required approvals and standards

Technical data for gas manifold

- Inlet pressure: Acetylene 25 bar, other gases 200/300 bar

- Working pressure: Acetylene 1.5 bar, other gases up to 20 bar

- Nominal flow rate: Acetylene 5 to 150 Nm3/h, Oxygen and high-compressed gases 30 to 320 Nm3/h

- Number of cylinders: up to 6 cylinders by default

- Number of bundles: up to 2 bundles by default

- Assembly: stainless steel mounting plate, plastic coated steel, cylinder connections with design-type tested non-return valve

- IBEDA supplies cylinder couplings, completely assembled gas manifolds with tapping points, pressure regulators, flashback arrestors and hoses.

Technical data tapping points and gas distributors

- Modular system

- Coated steel frame

- Colour coding for the gas type

- Ready for immediate use

- IBEDA flashback arrestors, tapping point regulators and fittings can be supplied on request.

IBEDA supplies mobile gas manifold stations for Oxygen as well as tapping points and gas distributors for Oxygen. Furthermore, IBEDA offers mobile gas manifolds for Acetylene, gas supply stations for Propane, gas manifold systems for Hydrogen and other technical, non-aggressive gases, such as Ethene and natural gas. Additionally, IBEDA supplied mobile gas manifold systems for CO2, tapping points and gas distributors for Nitrogen, Helium, CO2 and gas mixtures which are used for shielding gas welding (MIG/MAG, WIG), such as Argon/Helium and Argon/CO2.

The mobile gas manifold stations for Acetylene meet the safety related requirements as per the standard DIN EN 14114. These requirements are also valid for the stationary Acetylene manifolds. The equipment includes safety devices according to EN ISO 5175-1 at the outlet (decomposition arrestor) as well as a quick-action shut-off valve according to DIN EN 15615 in the high-pressure part downstream the pressure regulator. A manual shut-off valve is used with cylinder couplings up to 6 Acetylene cylinders.

The stationary central gas supply stations as well as the mobile manifolds are suitable for the supply of Oxygen and high-compressed gases from bundles or cylinders up to 300 bar.

Details - Mobile gas manifolds and tapping points

Mobile Gas manifold systems with tapping points

Mobile Gas manifold systems with tapping points

IBEDA mobile gas manifolds with integrated tapping points for Acetylene and all technical gases. Up to six workstations can be supplied simultaneously from two MCPs.

Cylinder connections for Propane and Oxygen

Cylinder connections for Propane and Oxygen

Heating application with an IBEDA ring burner. Gas supply from single cylinders connected by IBEDA cylinder connections. The cylinder connection units offer the possibility to have flexible greater withdrawal of gas from several cylinders if required. Cylinder connections are available for up to 6 cylinders of Acetylene and all technical gases.

Mobile gas manifold mounted at a MCP rack

Mobile gas manifold mounted at a MCP rack

IBEDA offer custom solutions for all applications requiring mobile use. The Acetylene supply from a MCP is provided by a mobile IBEDA gas manifold equipped with all necessary safety devices, such as quick-action shut-off valve and decomposition arrestor.

Mobile tapping point distributors with IBEDA safety devices

Mobile tapping point distributors with IBEDA safety devices

Mobile IBEDA tapping point distributors are utilized on shipyards, scrapyards and on construction sites