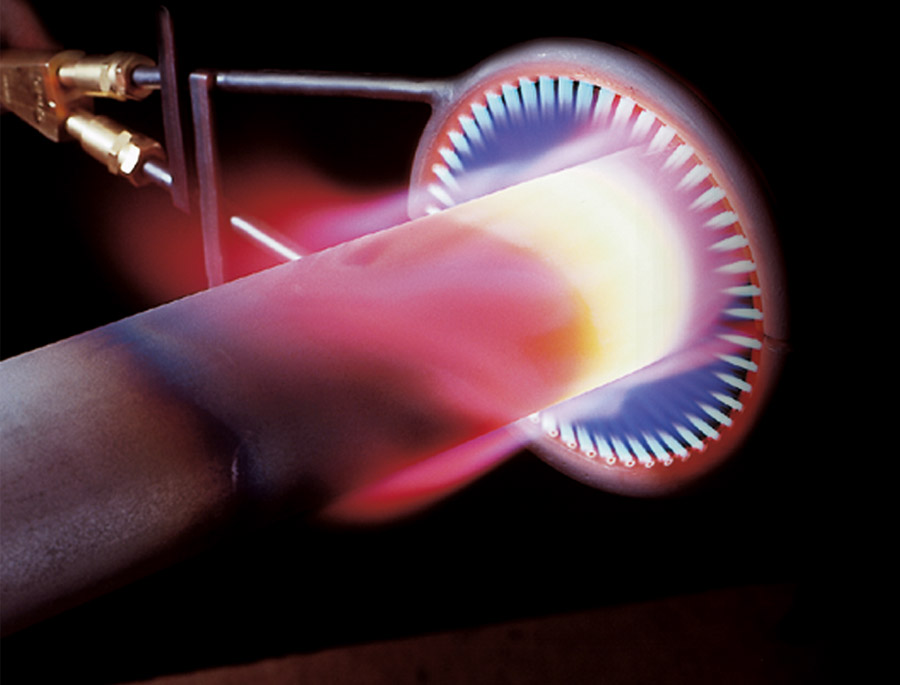

Heating burners for flame hardening

Applications

- Automobile manufacturing

- Tool manufacturing

- Machine tool manufacturing

- Steel and vessel manufacturing

Flame hardening is a process for surface finishing. Flame hardening means a hardening of the surface layer of a work piece and a low-heat treatment is required after hardening. The surface of the work piece is heated up quickly to the required hardening temperature and is cooled down by water quenching afterwards. The hardening burner and the water quench pass the work piece slowly. The depth which is to be hardened can be adjusted by changing the feed rate of the hardening burner. The distance between the hardening burner and the water quench influences the degree of hardness. The hardening burner and the quench are designed for the requirements of the work piece.

One advantage of flame hardening is the possibility to harden even very large and voluminous work pieces. Furthermore, the flame hardening is suitable for many different applications, even small lot sizes or single items.

The hardening burner can be used with fuel gases such as Acetylene, natural gas, Propane and Butane together with Oxygen. The required equipment for flame hardening includes standard flashback arrestors, hoses and pressure regulators.

IBEDA manufactures and supplies a wide range of flame hardening burners. Custom hardening burners can be designed according to the customer's specific requirement.